Introduction

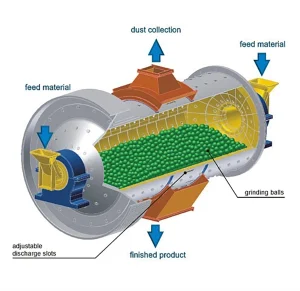

In industrial processes involving the grinding and milling of minerals, the ball mill serves as one of the key pieces of equipment, playing a decisive role in production efficiency. This machine uses grinding balls to reduce raw materials to very fine sizes, preparing them for subsequent processing stages. However, what ensures the durability and proper operation of a ball mill are its internal liners.

A ball mill liner is a wear-resistant, impact- and corrosion-resistant protective lining installed inside the mill shell. These liners can be made from various materials, including metal, rubber, polyurethane, and more, and are in direct contact with the materials being ground. Their main role is to protect the mill shell and optimize the motion of the grinding balls to maximize grinding efficiency.

Over time, these liners wear out and need to be replaced. Selecting the right type of liner not only extends the service life of the equipment but also significantly reduces maintenance costs and production downtime. This article explores the benefits of rubber liners, how to replace ball mill liners, mill shell inspection, and important safety considerations.

Liners and the Role of Internal Ball Mill Components

Liners come in various types, some of which include the following:

Lifter Bars: Lifter bars in ball mills and rod mills are used to lift and move the grinding balls or rods, facilitating the grinding and crushing of the feed material. Proper lifter bar design has a significant impact on grinding performance.

Shell Plates: Shell plates are positioned between the lifter bars in ball mills and rod mills and serve to protect the cylindrical metal shell.

Head Plates: Head plates are installed between the lifter bars in ball mills and protect the metal shell of the mill heads (the inlet and outlet sections of the ball mill).

Benefits of Rubber Liners

One of the advantages of rubber liners is their low weight, which reduces the load on the bearings and lowers energy consumption. Additionally, these liners can reduce noise levels by 8 to 10 decibels. The metal-rubber combination provides rubber liners with a longer service life compared to other types of liners.

Detailed Steps for Replacing Ball Mill Liners

1.Full Safety Measures: Power is disconnected and the mill is unloaded, with all balls removed.

2.Removal of Old Liners: Old liners are removed using pneumatic tools or a crane.

3.Extraction: Jacks or specialized rails are used to extract the liners safely.

4.Cleaning and Inspection: The shell is cleaned with compressed air, and cracks, corrosion, or damaged threads are inspected.

5.Addressing Issues: Any detected damage is repaired by welding, machining, or leveling.

6.Installation of New Liners: Liner components (shell plates, lifter bars, and head plates) are installed according to the customer’s design specifications.

7.Proper Torque: Bolts are tightened according to the manual, sealing is checked, and an empty load test is performed.

8.Performance Adjustment: A full load test is conducted, and noise, vibration, temperature, and milling efficiency are checked.

It should be noted that all procedures are performed by the skilled and experienced personnel of PIMCO.

Periodic Inspection and Maintenance

Visual Inspection: The liners are visually checked for surface wear and wear limits.

Thickness Measurement: Thickness is measured using gauges or 3D scanning, and compared with initial data to estimate the remaining service life.

External Inspection: Bolts, bearings, joints, and other external components are examined.

Routine Maintenance: Bearings are lubricated regularly.

Inspection After Changes in Load or Material: If the feed rate or material changes, an immediate inspection is carried out.

Warning Signs for Liner Replacement

ncreased Noise and Vibration: Indicates internal damage or loosening of the liners.

Increase in Coarse Particles in the Output: Signals reduced milling efficiency.

Machine Vibration: Suggests structural problems.

Reduced Liner Thickness: If the thickness falls below the safe limit, replacement is necessary.

Wear of Lifter Bars: Directly affects the milling performance and efficiency.

Conclusion

The ball mill is one of the key pieces of equipment in various industries, including mining and ceramic tile production, used for milling and grinding materials to produce powders at micron or even nano scales.

Rubber liners are selected in a fully engineered and customized manner according to operating conditions and production line requirements. The use of rubber liners provides an effective solution for reducing costs and improving performance.

By adhering to proper design principles, accurately following liner replacement procedures, and performing regular maintenance and inspections, longer operational life can be achieved, costly damage can be prevented, and milling efficiency can be optimized.