Peyman Sanat Moharekeh Sepahan Laboratory

The laboratory of Peyman Sanat Moharekeh Sepahan Company is one of the most vital and integral divisions of the organization, established with the aim of enhancing product quality and ensuring customer satisfaction. The laboratory’s activities cover the entire production process of rubber components, playing a crucial role in quality control and assurance of final products.Equipped with modern testing instruments and supported by a team of skilled and experienced specialists, the laboratory has earned recognition as a reliable and trusted reference center. It continuously strives to deliver high-quality services tailored to customer requirements.

At Peyman Sanat Moharekeh Sepahan Laboratory, a comprehensive quality evaluation process is implemented, from raw material inspection and daily compound production in the compounding unit to the testing of finished rubber components. With pride, through the execution of ongoing research and development projects, the laboratory contributes to improving product quality and extending the service life of components.

The laboratory conducts detailed examinations of the physical, mechanical, and rheological properties of rubber materials. Testing includes abrasion resistance, resilience, tensile and tear strength, adhesion strength, rheometry, hardness, aging resistance, chemical resistance, and compression set. All tests are performed in accordance with international standards and can be made available to valued customers and business partners upon request

Abrasion resistance test

The abrasion resistance test is a method used to measure the wear of a material against a rough surface under a specified and constant force. The test is conducted using a rotating cylindrical device fitted with an abrasive sheet. The rubber sample is placed on this sheet and undergoes wear as the cylinder rotates. The amount of rubber wear is reported in mm³ by measuring the changes in the sample’s weight and density.

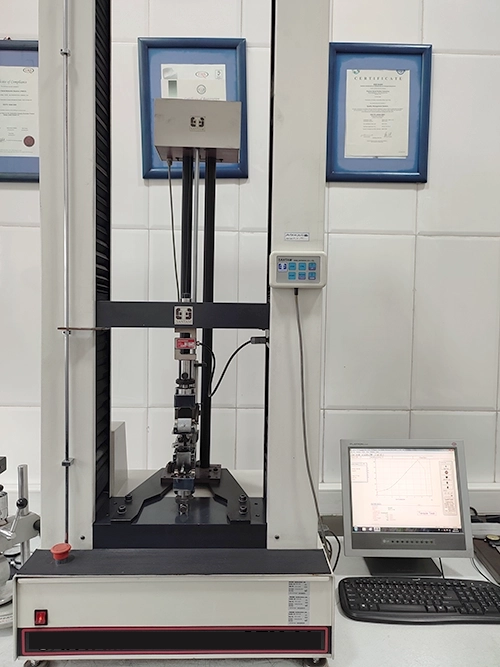

Tensile strength test

The tensile strength test is performed to measure the mechanical properties of rubber and elastomers. In this test, a rubber specimen of a specified shape is subjected to a uniform tensile force, and its deformation, stress, and strain are recorded. The test can determine various parameters, including tensile strength at break, elongation at break, and stress at a specified strain. This test is conducted in accordance with ASTM D412 standards.

Tear strength test

The tear strength test measures the resistance of a rubber specimen to the propagation of a deliberately introduced notch while under tensile force. The test reports the force required per unit thickness of the specimen, and it is conducted in accordance with ASTM D624 standards.

Resilience test

The resilience test involves releasing a pendulum of specified weight and mass from a 90-degree angle. The rebound angle is measured, and the difference in height between release and rebound is calculated. The final result is reported as a percentage of resilience, representing the proportion of energy lost due to the impact. This test is conducted in accordance with DIN 53512 standards.

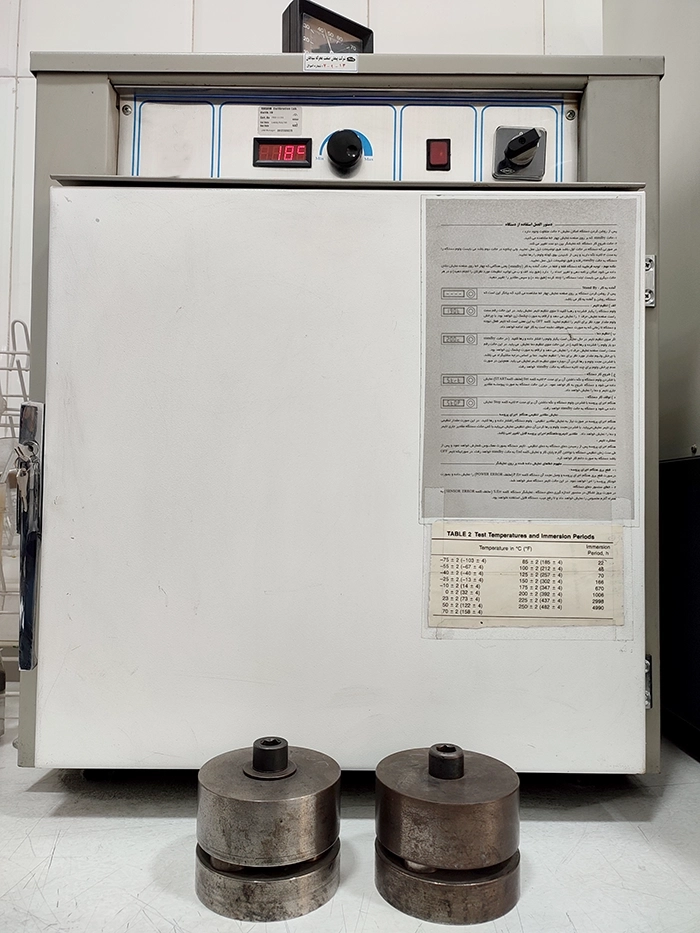

Compressive strength test

The compression set test is a method used to determine the ability of rubber to recover after being compressed at a specified temperature. This test is conducted in accordance with ASTM D395 standards. In this method, a rubber specimen is placed between two plates and compressed with a specified force, then held at the target temperature for a predetermined time. After removal from the plates, the final thickness of the specimen is measured. The compression set is calculated as the percentage change in thickness relative to the original thickness. A lower compression set indicates higher elasticity and less permanent deformation of the rubber.

Aging test

The aging test evaluates the effects of high temperatures on the properties of vulcanized rubber, such as hardness, tensile strength, elongation, resilience, abrasion, and more. Changes in the targeted properties are measured to assess material performance.

Rheometer test

The rheometer test is performed to determine the curing characteristics of raw rubber at a constant temperature. The rubber compound is placed between molds maintained at a fixed temperature, and continuous mechanical deformation is applied using the oscillation of the lower mold. The torque required for mold oscillation gradually increases as the rubber sample cures. The results derived from the torque–time curve of this test include scorch time, cure time, cure rate, and other related parameters. This test is conducted in accordance with ASTM D5289 standards.

Laboratory Banbury

The laboratory Banbury mixer is a specialized machine designed for blending rubber materials under precisely controlled speed and temperature conditions. Equipped with mixing rotors, it thoroughly combines the raw materials, and the resulting compound mass is then processed through a two-roll mill to achieve the desired thickness. This equipment plays a vital role in research and development projects, enabling accurate formulation and optimization of rubber compounds.